- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

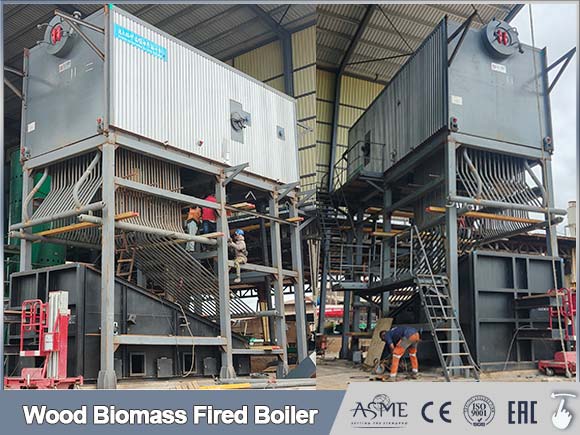

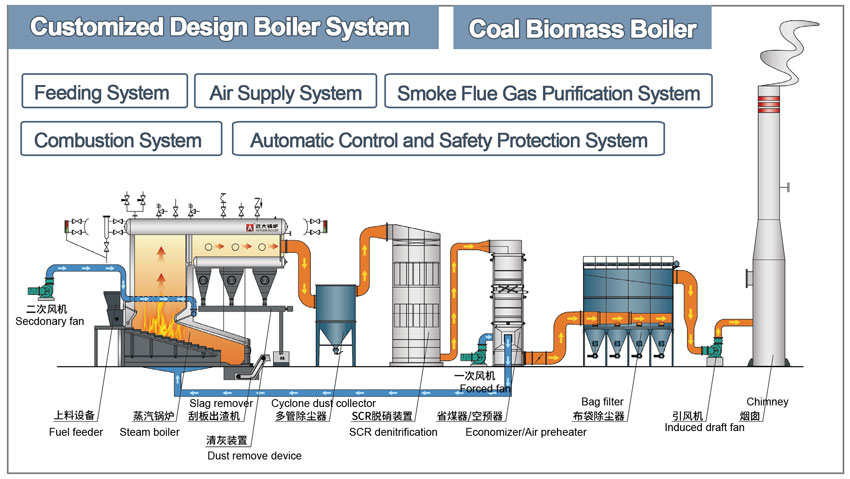

Water Tube Coal Biomass Boiler

- Capacity:2ton-75ton/h, 1.4mw-28mw

- Fuel:Biomass coal wood ricehusk shells bagasse solidwaste

- Pressure:0.1mpa-4.5mpa

- Application:For industrial production process, power generation

- Manufacture Standard:GB, ISO, CE, ASME, DOSH, EAC

Water Tube Boiler Coal Biomass

Yuanda Boiler supplies a wide range of solid fuel boilers for different industrial applications.

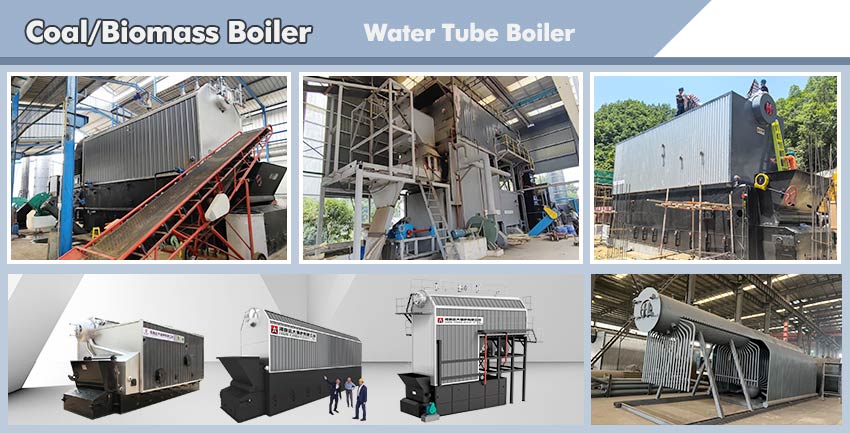

SZL SZW Water Tube Biomass Boiler

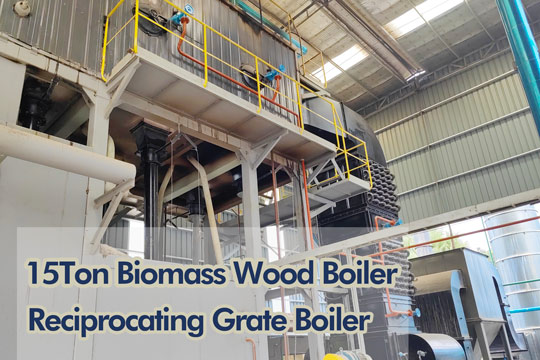

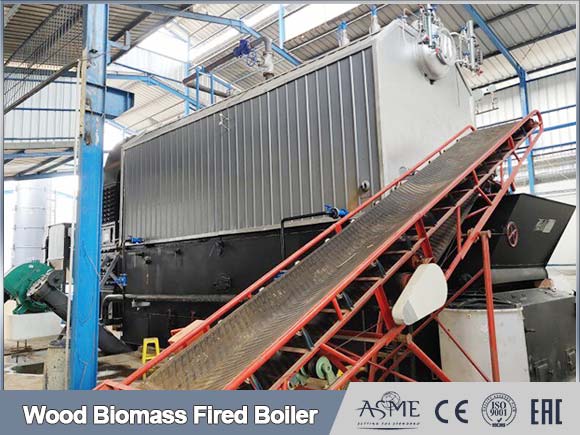

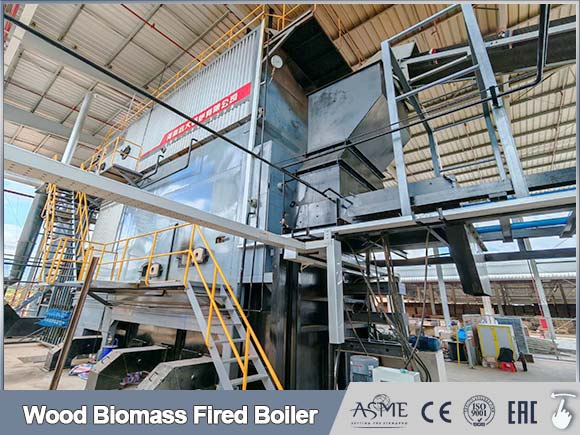

Yuanda SZL/SZW Series water tube boiler, adopt a double-drum offset furnace structure (D-type or A-type) and are available with chain grate or reciprocating grate stokers, delivering high efficiency, reliable operation, and eco-friendly, energy-saving performance.

Typecial fuel: biomass, coal, wood, rice husk, bagasse, palm kernel shell palm fibre, agro waste.

Technical Features SZL Boiler

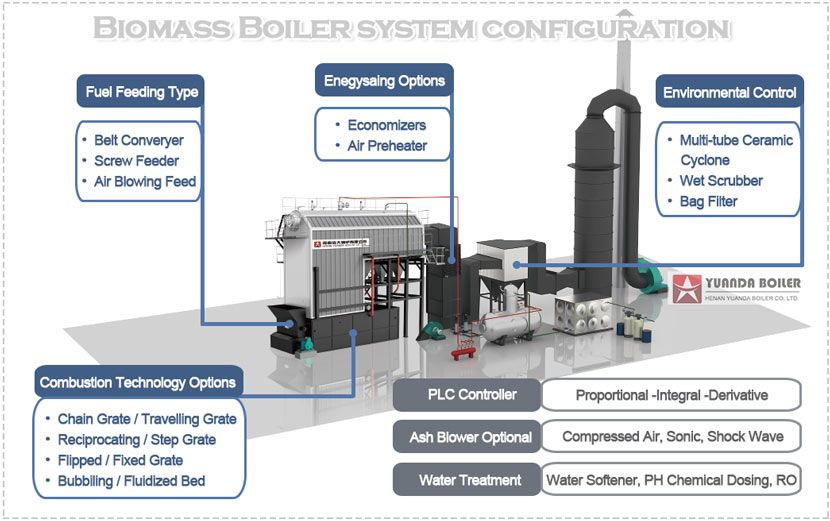

Intelligent Combustion Control System

1. Multi-zone air distribution: Air is supplied in sections along the grate length, with independent airflow control for each zone.

2. Real-time oxygen monitoring: Combustion air is automatically adjusted based on flue gas oxygen content to maintain optimal combustion.

3. Layered temperature control: Different grate zones are temperature-controlled to prevent local overheating and slagging.

Anti-Slagging Design

1. Optimized front and rear arches: Enhance heat radiation and gas mixing for stable ignition.

2. Special grate bars: High-temperature and oxidation resistant, with clinker-breaking structure.

3. Multi-stage ash cleaning: Combination of mechanical cleaning and soot blowers keeps heating surfaces clean.

Environmentally Compliant Emissions

1. Low-NOx combustion: Air staging and flue gas recirculation reduce NOx formation.

2. High-efficiency dust removal: Multi-cyclone or bag filter options meet strict emission standards.

3. Fly ash reuse: Collected ash can be reused as potassium fertilizer raw material, supporting resource recycling.

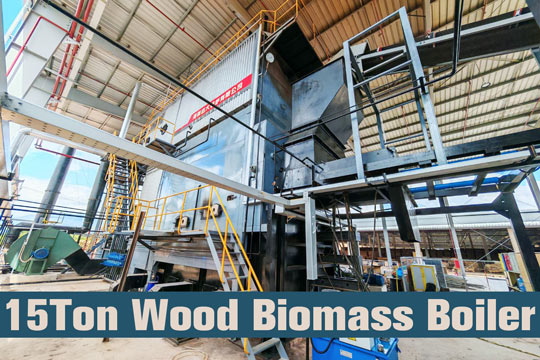

Typical Projects

Yuanda Biomass Coal Boiler, Qulified by ISO CE ASME DOSH, Global Sale Service Cover 100+ Countries & Regions.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. Our company established since 1956, over 70 years manufactureing experiences, 18 Years export experience.

2. Qualified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 135 countries all over the world, trustable quality & services for lifespan.

| SZL Series Steam Boiler Technical Parameter Table | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperature(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| SZL2 | 2 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >83.13 | 6.76 | 130.7 | 385.8 | 22 |

| SZL4 | 4 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.23 | 5.1 | 142 | 807 | 29 |

| SZL6 | 6 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.81 | 8.4 | 142 | 1209 | 34 |

| SZL8 | 8 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >85.02 | 9.4 | 149.1 | 1563.9 | 40.5 |

| SZL10 | 10 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.2 | 8.35 | 152.7 | 2149.3 | 24 |

| SZL12 | 12 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.56 | 12.8 | 148.7 | 2399.7 | 37 |

| SZL15 | 15 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.29 | 15.2 | 149.8 | 2568.4 | 24.7 |

| SZL20 | 20 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.8 | 15.5 | 147.4 | 4266.9 | 26 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

English

English

.png)