- Home

- Products

Oil Gas Boiler

Oil Gas Boiler

- WNS Series Liquid Fuel Oil Diese...

- Vertical Gas Lpg Diesel Hot Wate...

- SZS Series Double Drums Diesel G...

- Industrial Portable Skid-mounted...

- Waste Heat Recovery Steam Genera...

- Liquid Fuel Oil Bunker Diesel Oi...

- Liquid Fuel Waste Oil Bunker Oil...

- Gas Burner Boiler Natural Gas Lp...

- Oil Lpg Gas Hot Water Boiler

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- Small Solid Fuel Coal Heating Bo...

- SHX/DHX Series Bubbling Fluidize...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Industrial Solid Fuel Water Heat...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg Diesel Fired Thermal Oil...

- Solid Fuel Coal Wood Biomass The...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- YLW Series Horizontal Coal Therm...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Seires Vertical Wood Biomass...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

Boiler Surface Blowdown Based On TDS Value

18 / Sep

Why to use TDS value to control boiler surface blowdown ?

Advantges

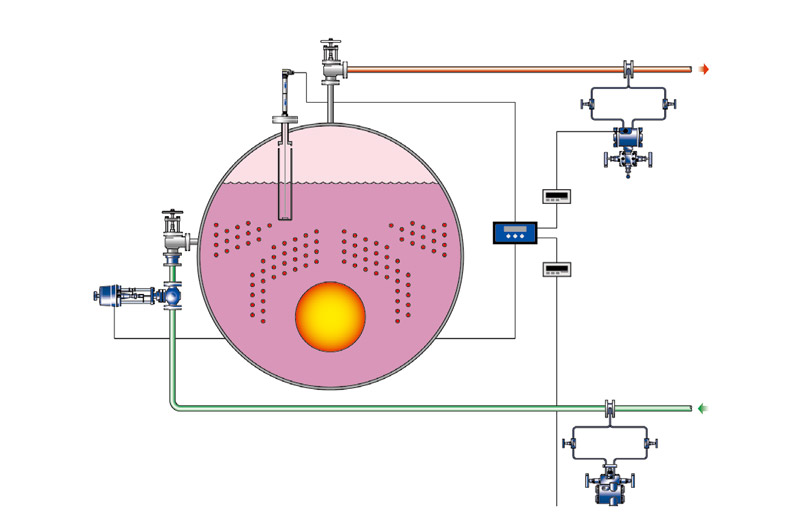

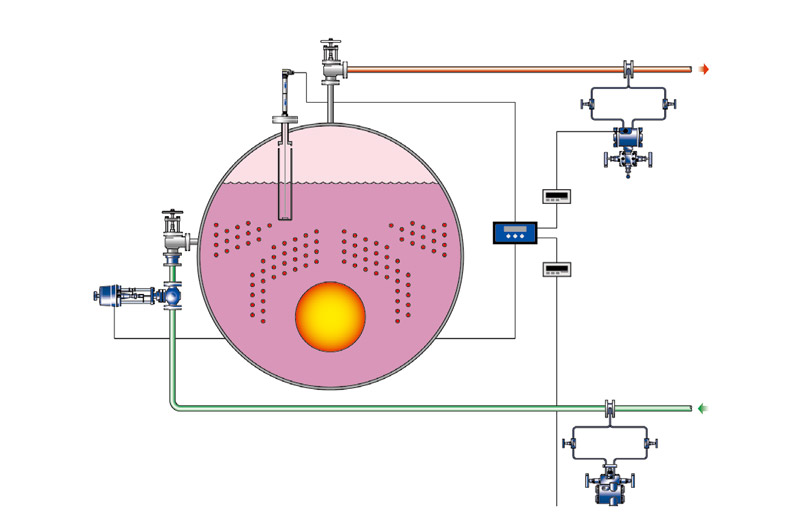

The best solution to boiler surface blowdown is automatic TDS blowdown. The sensor in the blowdown system regularly detects the TDS concentration of the boiler water, compares the detection results with the set value of the controller, and then controls the action of the blowdown valve. The use of automatic control can control the TDS concentration close to the maximum allowable value to avoid steam carryover and foaming caused by high TDS concentration. Precise control can reduce the amount of sewage to a minimum, save energy, and ensure steam quality. Greatly reduce operating costs.

Necessity of bottom TDS sewage discharge:

Excessive boiler bottom blowdown can cause great losses of heat energy and water treatment chemicals, so it is very important to keep the blowdown volume to a minimum.

In order to minimize energy loss and ensure that the total dissolved solids (TDS) concentration of the boiler water is controlled within the design range, it is recommended that the boiler also install an automatic TDS control system.

Principle:

The control system measures the conductivity of the furnace water, which is directly related to the concentration of dissolved solids (TDS). The conductivity of the boiler water is compared with the set value in the controller. If the conductivity is lower than the set value, the drain valve will close and remain closed at the end of flushing. If the conductivity is higher than the set value, the drain valve will remain open after flushing until the boiler water TDS is lower than the set value.

Any inquiry contact shirley@yuanda-boiler.com

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible

Copyright © Henan Yuanda Boiler Corporation Ltd. All Rights Reserved Site Index

Privacy policy

English

English

.png)