- Home

- Products

Oil Gas Boiler

Oil Gas Boiler

- WNS Series Liquid Fuel Oil Diese...

- Vertical Gas Lpg Diesel Hot Wate...

- SZS Series Double Drums Diesel G...

- Industrial Portable Skid-mounted...

- Waste Heat Recovery Steam Genera...

- Liquid Fuel Oil Bunker Diesel Oi...

- Liquid Fuel Oil Bunker Burner Bo...

- Gas Burner Boiler Natural Gas Lp...

- Industrial Biomethane Digester G...

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- Small Hot Water Heater Boiler Ve...

- SHX/DHX Series Circulating Fluid...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Industrial Solid Fuel Water Heat...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg Diesel Fired Thermal Oil...

- Biomass Wood Thermal Oil Boiler ...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- YLW Series Horizontal Coal Therm...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Seires Vertical Wood Biomass...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

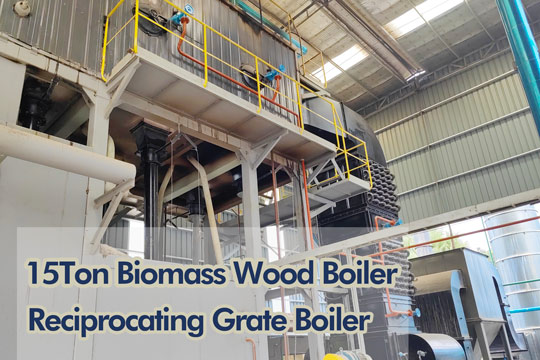

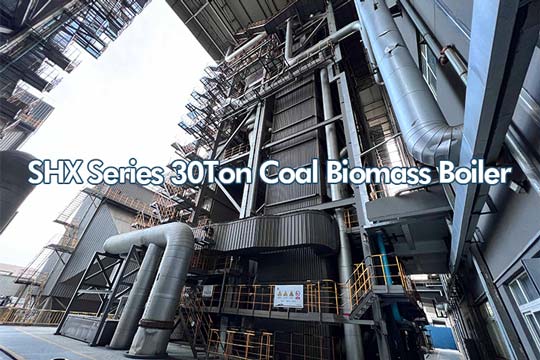

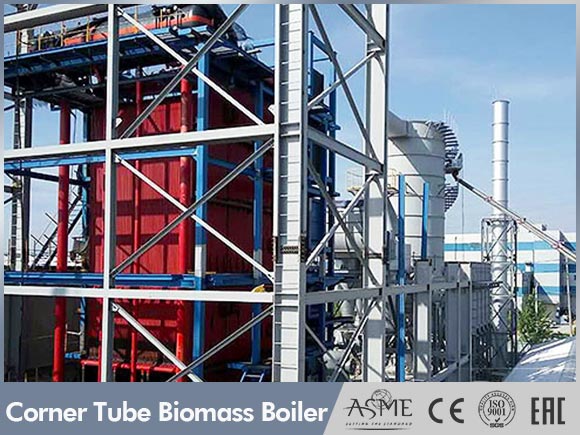

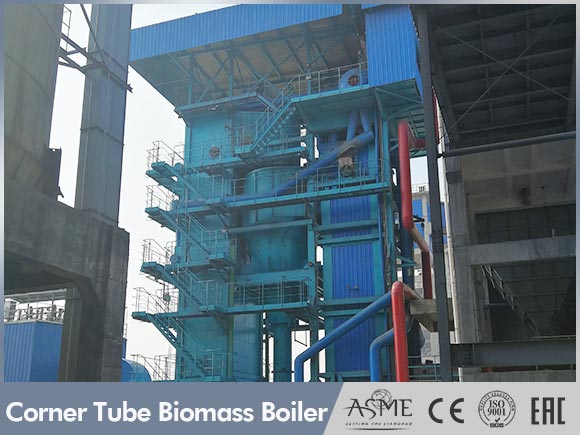

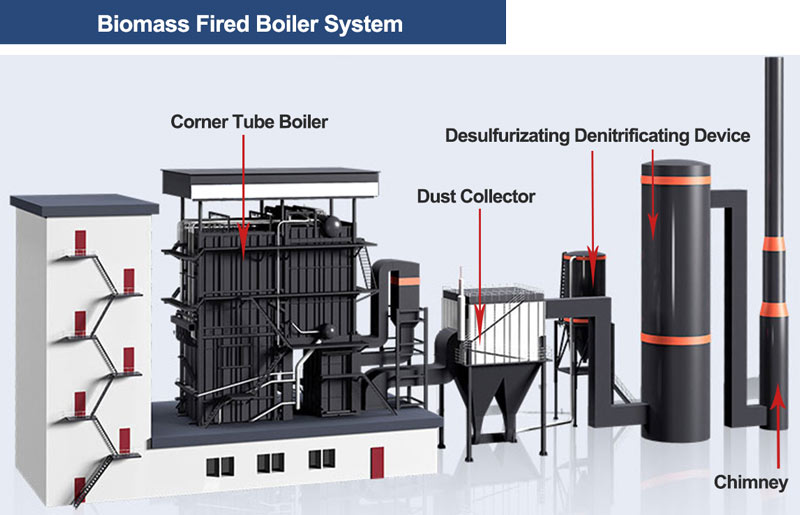

DHL DHW Corner Tube Biomass Boiler Cross Drum Water Tube Biomass Boiler

- Thermal Capacity:20ton-75 ton/hr

- Working Pressure:1.25MPa-4.5MPa

- Fuel:Biomass, bagasse, woodchip, corn cob, sawdust, palm shells, ricehusk

- Structure:Corner Tube Boiler Single drum Boiler

- Application:Power generation, industries production heating, central heating...

DHL DHW Biomass Water Tube Boiler

Yuanda DHL DHW Corner Tube Boiler is a compact and efficient boiler that utilizes a pipe system as its skeleton. It features a fully enclosed membrane wall structure, flag tube design for the convective heating surface, and is widely used due to its compact structure and rapid temperature rise. It is a bulk-structured boiler.

1. Broad Fuel Compatibility

Compatible with biomass pellets, rice husks, wood chips, corn cobs, sawdust etc.

2. High Combustion Efficiency

Cross-beam chain grate and membrane water-cooled wall ensure thorough fuel combustion

3. High Degree of Intelligence

Advanced control, automated fuel, ash, slag operations

4. Customizable Boiler System

Tailored solutions for feed, slag, and gas treatment, saving time and money

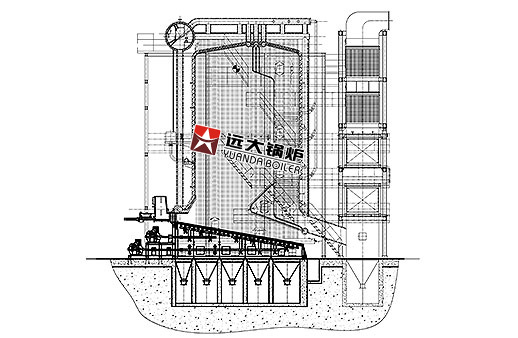

Structure of DHL DHW Biomass Boiler

1. The four corners of the corner tube hot water boiler are large-diameter thick-walled downcomers, the boiler is consist with downcomers, boiler drum, water-cooled wall, header, flag-shaped heating surface, and reinforcing beam. No steel frame structure,

2. The drum of the angle tube hot water boiler is external longitudinal arranged or a horizontal arranged, the furnace outlet is arranged at a high position, and the combustion space is relatively sufficient.

3. Fully enclosed membrane water-cooled walls are used around the furnace and the heating surface channel, the furnace has a large cross-sectional area and large volume.

4. Adopts unique flag-type heating surface structure technology, a large number of convection heating surface tubes are led out of the film-type water-cooled wall tubes to form a heating surface like a banner.

5. The grate of the corner tube boiler adopts the scale type or beam type grate, which adopts the isobaric structure of the gale bin. Below the grate surface is a large isobaric chamber. Between the isobaric air bunker and the grate face are several group

6. Could arrange secondary air on the front wall and rear wall of the furnace according to the different fuel types.

7. Economizer or air preheater is arranged at the rear of the boiler, which can absorb the heat of the flue gas, reduce the flue gas exhaust temperature, save energy, and improve efficiency.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

2. Qualified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 132 countries all over the world, trustable quality & services for lifespan.

| DHL DHW Series Biomass Steam Boiler | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | Thermal efficiency(%) | Feed water temperature | ||||

| DHL/DHW 20 | 20 | 1.25Mpa-4.5Mpa | 194°C-450°C | 88% | 105°C | ||||

| DHL/DHW 25 | 25 | 88% | 105°C | ||||||

| DHL/DHW 30 | 30 | 88% | 105°C | ||||||

| DHL/DHW 35 | 35 | 88% | 105°C | ||||||

| DHL/DHW 40 | 40 | 88% | 105°C | ||||||

| DHL/DHW 50 | 50 | 88% | 105°C | ||||||

| DHL/DHW 60 | 60 | 88% | 105°C | ||||||

| DHL/DHW 70 | 70 | 88% | 105°C | ||||||

| The basic parameter table provided is a reference, Yuanda Boiler can tailor the boiler device and system to your specific needs. For additional specifications, please contact us. | |||||||||

Chinese

Chinese

English

English

.png)