- Home

- Products

Oil Gas Boiler

Oil Gas Boiler

- WNS Series Liquid Fuel Oil Diese...

- Vertical Gas Lpg Diesel Hot Wate...

- SZS Series Double Drums Diesel G...

- Industrial Portable Skid-mounted...

- Waste Heat Recovery Steam Genera...

- Liquid Fuel Oil Bunker Diesel Oi...

- Liquid Fuel Waste Oil Bunker Oil...

- Gas Burner Boiler Natural Gas Lp...

- Industrial Biomethane Digester G...

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- Small Hot Water Heater Boiler Ve...

- SHX/DHX Series Bubbling Fluidize...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Industrial Solid Fuel Water Heat...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg Diesel Fired Thermal Oil...

- Solid Fuel Coal Wood Biomass The...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- YLW Series Horizontal Coal Therm...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Seires Vertical Wood Biomass...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

High Pressure Coal Wood Biomass Steam Boiler Saturated or Superheated Steam Generation Boiler

- Our Products:Steam Boiler, Steam Generator, Hot Water Boiler, Thermal Oil Boiler, Thermic Fluid Heater, Hot Air Furnace

- Fuel:Biomass, coal, wood, ricehusk, bagasse, solid waste

- Steam Pressure:0.1-3.8Mpa; 1-38Bar

- Usage:industrial heating drying process, Power generation

- Manufacture Standard :GB, ISO, CE, ASME, DOSH, EAC

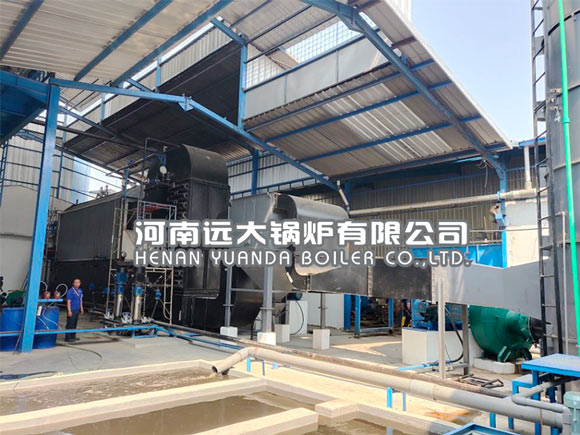

SZL Biomass Boiler

(Use biomass, biomass waste, husk, palm shells, palm fibre, bagasse, coconuts, sawdust, ect)

SZL water tube biomass boiler, is double drums offset furnace structure ("D" type series or "A" type series). Its has advantages of high technology, environmental and energy saving.

Yuanda SZL Boiler Advantages:

1. With Built-in Steam Separator

2. High efficiency with various biomass waste fuels

2. With Built-in Air Distribution Piping inside arch

3. Resistance to Corrosion & Slagging Processing in Convection Heating Area

Technical Features:

1. Cyclone 2nd-burning furnace

Design the cyclone chamber structure in furnace, help second combustion and dust separation, achieve dust removal, energy saving and environmental protection.

2. Special Air Wind Chamber Design

Independ wind chamber structure, improve the biomass fuel burning efficiently, help protect boiler pipes, avoid bad effect for boiler sturcture.

3. Special Large Furnace Design

Large furnace volume, strong adaptability for biomass fuel & solid waste, such as husk, palm shells, coconuts, peanut shells, walnut shells.

4. Double Drums & Membrane Water Wall

Membrane water wall construction, increase high heat transfer coefficient, good heat transfer effect, low heat loss, good air tightness and good performance of furnace wall.

.jpg)

Boiler Safety Operation Assurance

1. Water level protection

2. Over pressure protection

3. Exhausted smoke over temperature protection

4. Design with the 5th Water level detector

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 103 countries all over the world, trustable quality & services for lifespan.

| SZL Series Steam Boiler Technical Parameter Table | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperation(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| SZL2 | 2 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >83.13 | 6.76 | 130.7 | 385.8 | 22 |

| SZL4 | 4 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.23 | 5.1 | 142 | 807 | 29 |

| SZL6 | 6 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.81 | 8.4 | 142 | 1209 | 34 |

| SZL8 | 8 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >85.02 | 9.4 | 149.1 | 1563.9 | 40.5 |

| SZL10 | 10 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.2 | 8.35 | 152.7 | 2149.3 | 24 |

| SZL12 | 12 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.56 | 12.8 | 148.7 | 2399.7 | 37 |

| SZL15 | 15 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.29 | 15.2 | 149.8 | 2568.4 | 24.7 |

| SZL20 | 20 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.8 | 15.5 | 147.4 | 4266.9 | 26 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Chinese

Chinese

English

English

.png)