- Home

- Products

Oil Gas Boiler

Oil Gas Boiler

- WNS Series Liquid Fuel Oil Diese...

- Vertical Gas Lpg Diesel Hot Wate...

- SZS Series Double Drums Diesel G...

- Industrial Portable Skid-mounted...

- Waste Heat Recovery Steam Genera...

- Liquid Fuel Oil Bunker Diesel Oi...

- Liquid Fuel Waste Oil Bunker Oil...

- Gas Burner Boiler Natural Gas Lp...

- Industrial Biomethane Digester G...

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- Small Hot Water Heater Boiler Ve...

- SHX/DHX Series Bubbling Fluidize...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Industrial Solid Fuel Water Heat...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg Diesel Fired Thermal Oil...

- Solid Fuel Coal Wood Biomass The...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- YLW Series Horizontal Coal Therm...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Seires Vertical Wood Biomass...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

Industrial Biomass Husk Boiler

- Our Products :Steam Boiler, Steam Generator, Hot Water Boiler, Thermal Oil Boiler, Thermic Fluid Heater, Hot Air Furnace

- Capacity:0.5ton-75ton

- Fuel:biomass, rice husk, palm kernel shells, sawdust, solidwaste

- Usage:Rice mill parboiling drying, Power generation, Industrial use

- Manufacture Standard :GB, ISO, CE, ASME, DOSH, EAC

Biomass Husk Fired Boiler

1. Mostly ricehusk boiler used in rice mill, supply steam for parboiling and drying process in rice mill 10tpd-1000tpd.

2. Yuanda husk fired boilers, have been used in rice mill, textile industry, refinery oil mill, food factory......Yuanda Products have sold to Nepal, Pakistan, Uganda, Nigeria, Bangladesh, Colombia, South Africa, Myanmar, Vietnam, Indonesia, etc. Global service for boiler installation guiding, training operators, we offer whole life service for customes' boiler.

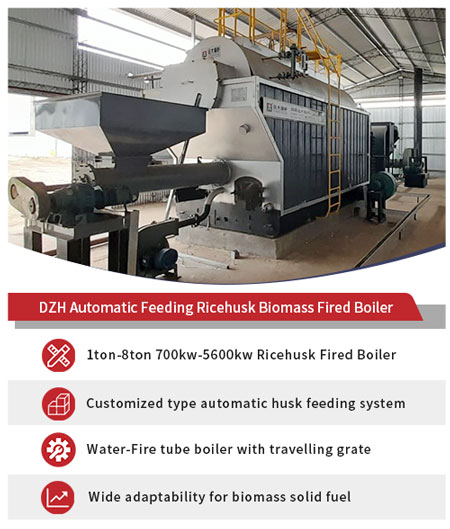

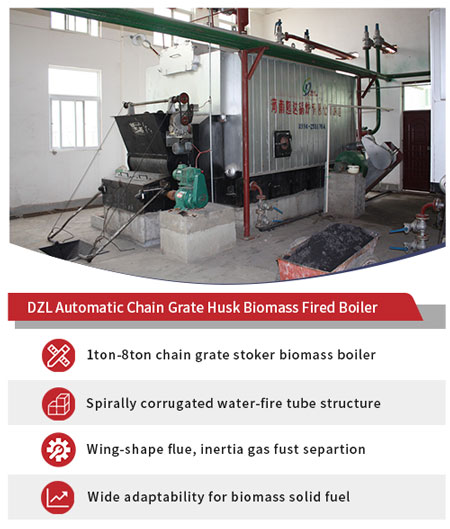

DZL Chain Grate Husk Fired boiler

DZL biomass rice husk boilers are horizontal three-pass water & fire tube boilers with a chain grate stoker structure. Threaded pyrotechnic tubes are arranged in the drum to form a convection heating surface,while the drum and the water walls on both sides from a radiation heating surface in the furnace.

1. Large stove space for ricehusk burning.

Rice husks have a low ignition point, high volatile content, and are flammable and light. In order to prevent the rice husks from being blown out of the furnace before they burn out, increase the distance between the front and rear arches.

2. Optimal boiler water pipes thickness and surface anti-wear processing

Thicken the boiler water pipes and do some anti-wear processing measures on the water pipe surface. So increasing the heating area and strength heat transfer efficiency, make full use of fuel heat power and produce more steam, make the boiler output more stable.

3. Reasonable control for rice husk thickness and grate speed

when ricehusk burning in stove. The preferable amount of forced air and induced air aim to let the rice husk burning in a semi-suspended state on the fire grate.

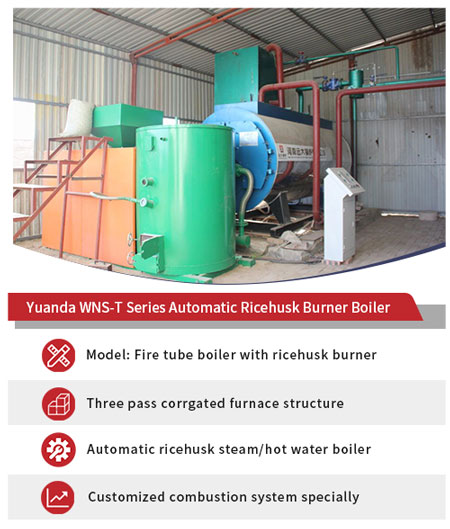

WNS Biomass Husk Burner Boiler

Husk burner fire tube boiler, its a special husk boiler because of external biomass burner.

Consist of furnace boiler body and husk burner. How it work ? husk-fuel is feed into biomass burner, then burning and purging fire into furnace, release heat energy into boiler body, flue gas three pass way, high-efficiency adsorb the energy.

Complete rice milling equipment with ricehusk boiler

Rice mill machine, complete set machine for rice parboiling and drying, availble for production 18t/day to 300t/day, including machines like husker, destoner, rice grader, color sorter, paddy dryer, etc. Know More By Shirley@yuanda-boiler.com

Process: Paddy Cleaner → Destoner→Paddy Separator→Rice Whitener→Rice Grader→water polisher→Color Sorter→Packing

.jpg)

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

2. Qualified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 132 countries all over the world, trustable quality & services for lifespan.

| DZ Series Steam Boiler Technical Parameter Table | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperation(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| DZH1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 127.25 | 192.32 | 9 |

| DZL1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 113.34 | 190.42 | 13.5 |

| DZH2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.75 | 126.41 | 386.47 | 15 |

| DZL2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.77 | 106.34 | 393.77 | 22 |

| DZH4 | 4 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 7.7 | 137.25 | 782.29 | 18.5 |

| DZL4 | 4 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.2 | 124.49 | 756.89 | 27.6 |

| DZH6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 7.4 | 146.83 | 1169.57 | 25 |

| DZL6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.1 | 137.29 | 1148.68 | 35 |

| DZL8 | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 9.6 | 141.06 | 1602.44 | 38 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Chinese

Chinese

English

English

.png)

.jpg)