- Home

- Products

Oil Gas Boiler

Oil Gas Boiler

- WNS Series Liquid Fuel Oil Diese...

- Vertical Gas Lpg Diesel Hot Wate...

- SZS Series Double Drums Diesel G...

- Industrial Portable Skid-mounted...

- Waste Heat Recovery Steam Genera...

- Liquid Fuel Oil Bunker Diesel Oi...

- Liquid Fuel Waste Oil Bunker Oil...

- Gas Burner Boiler Natural Gas Lp...

- Industrial Biomethane Digester G...

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- Small Hot Water Heater Boiler Ve...

- SHX/DHX Series Bubbling Fluidize...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Industrial Solid Fuel Water Heat...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg Diesel Fired Thermal Oil...

- Solid Fuel Coal Wood Biomass The...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- YLW Series Horizontal Coal Therm...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Seires Vertical Wood Biomass...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

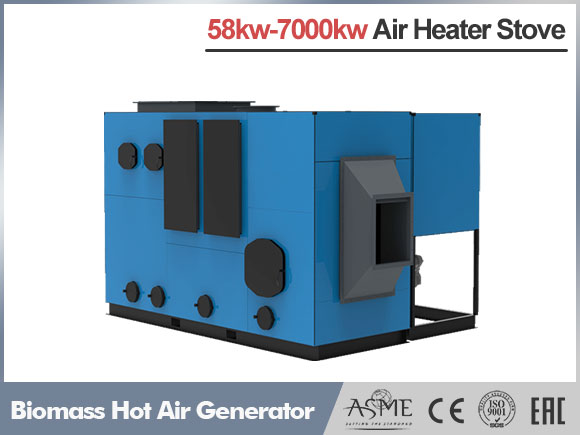

Biomass Hot Air Generator Furnace

- Capaciity:Customized

- Hot air outlet temperature:60-800℃

- Pressure:Customized

- Fuel:Biomass pellet, wood pellet, solid waste

- Manufacture Standard:ISO CE ASME DOSH EAC

Biomass Hot Air Generator Stove

Industrial biomass hot air generator stove, consists of stove furnace and feeding system and intelligent control system.

1. The characteristics are fast heating and good heat exchange effect. No other auxiliary equipment is needed. It can directly exchange air with air to provide users with clean and efficient hot air to meet the needs of different working conditions.

2. The furnace body adopts the most advanced combustion technology, a new generation of combustion method developed according to the combustion characteristics of biomass particles. The heat exchanger adopts a baffle return method to increase the time that the high-temperature flue gas stays in the heat exchanger, fully release heat, and improve thermal efficiency.

Design Advantages:

1. Cleaner and more efficient: The barbed heat exchange tube recovers waste heat, the number of winds in the boiler is small, and the air in and out is fast.

2. High thermal utilization rate: air inlet in the low temperature area; air outlet in the high temperature area, the highest air outlet is 500℃

3. Quality assurance: not easy to deform, the furnace life is more than 5 years.

4. Low emission: meet regional environmental protection standards

Why Choose Us ?

1. We offer all kinds of boiler machine, customized service for customers' demand, send your specific details to us.

2. 60+Years' experience in boiler design, technique, production, installation and operation. 10+Years export boiler experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

Global Worldwide Service

1. Offer catalogue, various boiler model for choose, inquire one you prefer.

2. Technical discussion on boiler system solution for your company use.

3. Warmly welcome all customers come to visit the production base

4. Trustable after sale service, for boiler installation, training operators.

5. Whole life service for boiler consult, contact us whenever.

6. Yuanda products have covered all provinces and cities of China and have been exported to 90 countries and regions such as Bangladesh, Nigeria, Chile, Russia, etc. More than 8000+ boiler projects worldwide !

| Model | FWHS0.058 | FWHS0.088 | FWHS0.12 | FWHS0.175 | FWHS0.24 | FWHS0.35 | FWHS0.54 | FWHS0.7 | FWHS1.05 | FWHS1.4 | FWHS1.75 | FWHS2.1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Working Pressure | Atmospheric pressure | |||||||||||

| Thermal Efficiency | 88% | |||||||||||

| Rated Capacity kw | 58 | 88 | 120 | 175 | 240 | 350 | 540 | 700 | 1050 | 1400 | 1750 | 2100 |

| Rated Capacity (*10000) kcal | 5 | 7.5 | 10 | 15 | 20 | 30 | 45 | 60 | 90 | 120 | 150 | 180 |

| Induced Fan (w) | 120 | 370 | 370 | 550 | 750 | 1100 | 1500 | 1500 | 2200 | 2200 | 3000 | 3000 |

| Forced Fan (w) | 120 | 240 | 240 | 330 | 400 | 550 | 370 | 550 | 1500 | 1500 | 1500 | 2200 |

| Fuel Consumption | 11.95 | 17.92 | 23.29 | 35.84 | 47.89 | 71.68 | 107 | 143 | 215 | 286 | 358 | 430 |

| Chimney Diameter(mm) | 140 | 165 | 165 | 165 | 165 | 165 | 273 | 273 | 350 | 350 | 350 | 350 |

| Transportation Weight(kg) | 828 | 1000 | 1150 | 1360 | 1460 | 1650 | 1980 | 2370 | 3120 | 4100 | 5200 | 6150 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | ||||||||||||

Chinese

Chinese

English

English

.png)