- Home

- Products

Oil Gas Boiler

Oil Gas Boiler

- WNS Series Liquid Fuel Oil Diese...

- Vertical Gas Lpg Diesel Hot Wate...

- SZS Series Double Drums Diesel G...

- Industrial Portable Skid-mounted...

- Waste Heat Recovery Steam Genera...

- Liquid Fuel Oil Bunker Diesel Oi...

- Liquid Fuel Waste Oil Bunker Oil...

- Gas Burner Boiler Natural Gas Lp...

- Industrial Biomethane Digester G...

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- Small Hot Water Heater Boiler Ve...

- SHX/DHX Series Bubbling Fluidize...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Industrial Solid Fuel Water Heat...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg Diesel Fired Thermal Oil...

- Solid Fuel Coal Wood Biomass The...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- YLW Series Horizontal Coal Therm...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Seires Vertical Wood Biomass...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

Greenhouse Hot Water Heater Boiler

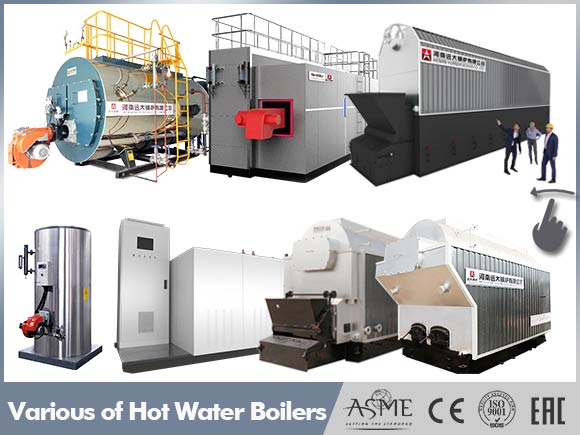

- Products:Fuel Oil Diesel Boiler, Gas Boiler, Coal Boiler, Biomass Wood Boiler, Electrical Boiler

- Thermal Heat Power:100kw-35000kw, 100000kcal-12Mkcal

- Heat Water Temperature:50°C-130°C

- Usage:For central heating in buildings, greenhouse, camp, hotel

- Manufacture Code:ISO CE ASME EAC

Industrial Water Heater Boiler In Greenhouse

Hot water boilers and coil fans together work for heating system in greenhouses for planting flowers, fruits, vegetables, etc. For heating area above 300 sqm, 5000 sqm, 10000 sqm, 20000 sqm.......

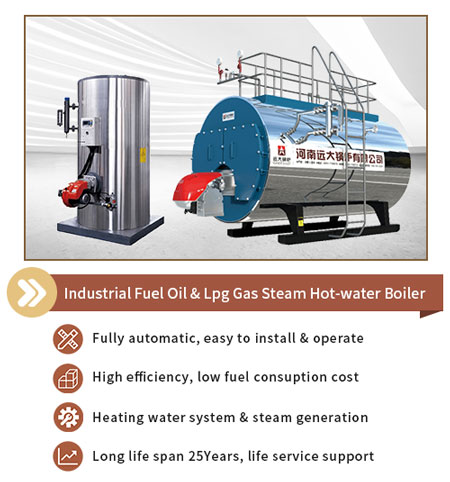

Solution A Oil Gas Fired Boiler

1. 100kw to 14000kw Automatic hot water heating boiler, powered by gas, lpg, diesel, light oil, heavy oil, cng, exhaust gas.

2. We supply kinds of gas/oil powered hot water boilers, such as vertical type boiler, horizontal type boiler, fire tube boiler, water tube boiler, modular hot water boiler, vacuum hot water boiler.

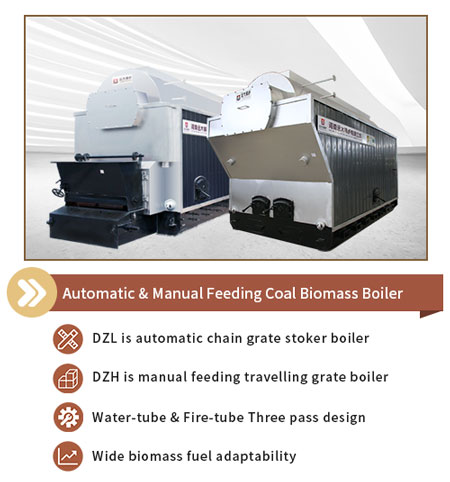

Solution B Solid Fuel Boiler (Coal Wood Biomass Boiler)

1. Availble fuel: coal, wood, biomass, woodpellets, ricehusk, palmshells, palmfibre, coconuts, solid waste.

2. We supply small hot water boiler & large heavy duty hot water boiler. Supply boiler scale in 100kw to 35000kw. Widely used in factory production processing & heating space in buildings.

3. Most popular: vertical coal boiler, chain grate coal/biomass boiler, manual type travelling grate wood boiler, water tube biomass boiler. Dear, pls send your need boiler details(describ the usage), we will give a recommend for suitable model.

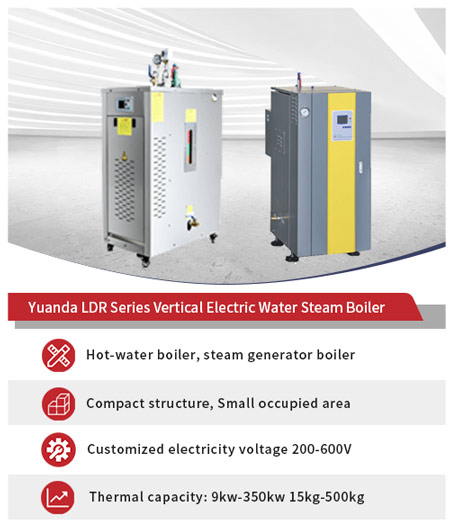

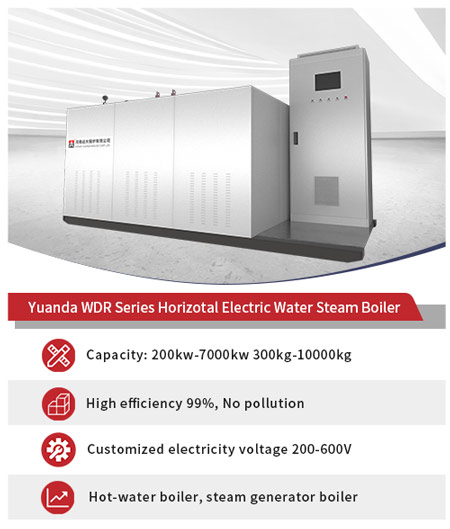

Solution C Electric Boiler

Electrically heated water boiler, also said "electric hot water heater" "electric hot water boiler" "industrial electric water heater".

We supply electric heating boiler capacity in 35kw to 3500kw. If you need small capacity, choose vertcal electric boiler is enough, otherwise, choose large horizontal type electric boiler.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 103 countries all over the world, trustable quality & services for lifespan.

| Model | Rated power(MW) | Rated pressure (Mpa) | Rated output temperature(℃) | Rated return water temperature(℃) | Thermal efficiency(%) | Exhaust temperation(℃) | Fuel comsumption | max transportation weigh(t) | |

|---|---|---|---|---|---|---|---|---|---|

| light diesel oil(kg/h) | natural gas(Nm³/h) | ||||||||

| WNS0.35 | 0.35 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 31.6 | 36.6 | 2.65 |

| WNS0.7 | 0.7 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 60.4 | 69.3 | 4.66 |

| WNS1.4 | 1.4 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 122.8 | 146.1 | 6.53 |

| WNS2.1 | 2.1 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 192.3 | 227.1 | 7.3 |

| WNS2.8 | 2.8 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 246.1 | 286.5 | 8.1 |

| WNS4.2 | 4.2 | 0.7/1.0/1.25 | 95/115/130 | 70 | >97 | 60-75 | 367.1 | 412.6 | 15.1 |

| WNS5.6 | 5.6 | 0.7/1.0/1.25/1.6 | 95/115/130 | 70 | >97 | 60-75 | 490.2 | 543.7 | 18.2 |

| WNS7.0 | 7.0 | 0.7/1.0/1.25/1.6 | 95/115/130 | 70 | >97 | 60-75 | 593.6 | 660.7 | 25.6 |

| WNS10.5 | 10.5 | 0.7/1.0/1.25/1.6 | 95/115/130 | 70 | >97 | 60-75 | 936.5 | 998.8 | 29.1 |

| WNS14.0 | 14.0 | 0.7/1.0/1.25/1.6 | 95/115/130 | 70 | >97 | 60-75 | 1200.8 | 1330.7 | 47.8 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Chinese

Chinese

English

English

.png)

.jpg)