- Home

- Products

Oil Gas Boiler

Oil Gas Boiler

- WNS Series Liquid Fuel Oil Diese...

- Vertical Gas Lpg Diesel Hot Wate...

- SZS Series Double Drums Diesel G...

- Industrial Portable Skid-mounted...

- Waste Heat Recovery Steam Genera...

- Liquid Fuel Oil Bunker Diesel Oi...

- Liquid Fuel Oil Bunker Burner Bo...

- Gas Burner Boiler Natural Gas Lp...

- Industrial Biomethane Digester G...

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- Small Hot Water Heater Boiler Ve...

- SHX/DHX Series Bubbling Fluidize...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Industrial Solid Fuel Water Heat...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg Diesel Fired Thermal Oil...

- Solid Fuel Coal Wood Biomass The...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- YLW Series Horizontal Coal Therm...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Seires Vertical Wood Biomass...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

Biomass Tree Log Wood Chipper Crusher

- Capacity:3-20tph

- Finished Product Size:1-50mm

- Voltage:380V, Customerized

- Transport Package:Wooden Case or Container

- Final product:Customized Sawdust/Wood chips

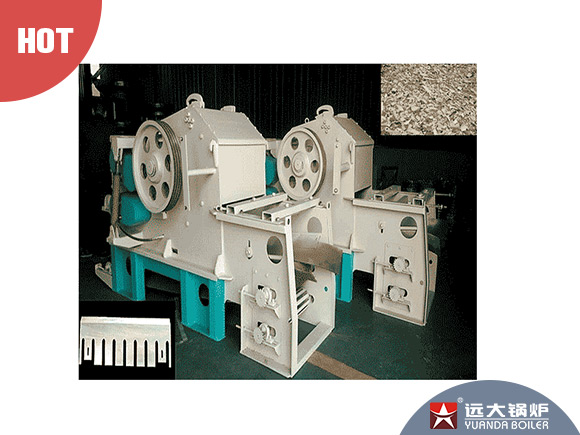

Wood Chipper, Wood Crusher

Wood chipper/wood chipper shredder is mainly used to crush big wood logs or wood timber, plywood, wood branches, furniture waste into small chips, the thickness of last chips is 3mm-5mm, length and width is about 15-30mm, it is wood chips not wood sawdust. By adjusting knives gap, outlet chips dimension will be adjusted

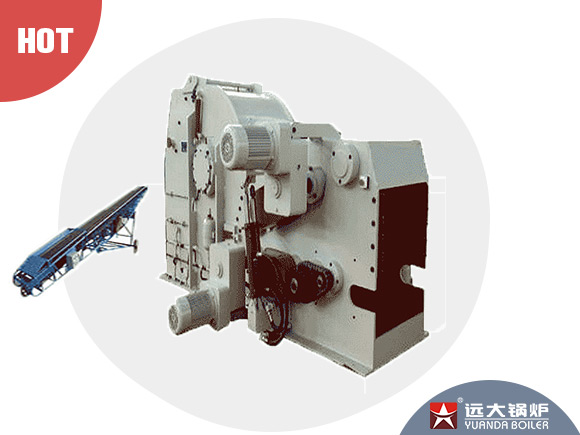

Structure

1. It mainly consists of body, knife roller, top and bottom feed mechanism, feeding device, hydraulic system.

2. Knives was fixed on the roller by special bolts. As different thickness of raw material, the top feed mechanism could be adjusted automaticly, then chips drop through screen, chipping again for large size material.

3. By hydraulic system, the cover shell of machine could be opened freely, easy for user to replace the parts and knives, also convenient for adjusting the space between knives and dead knives.

Application

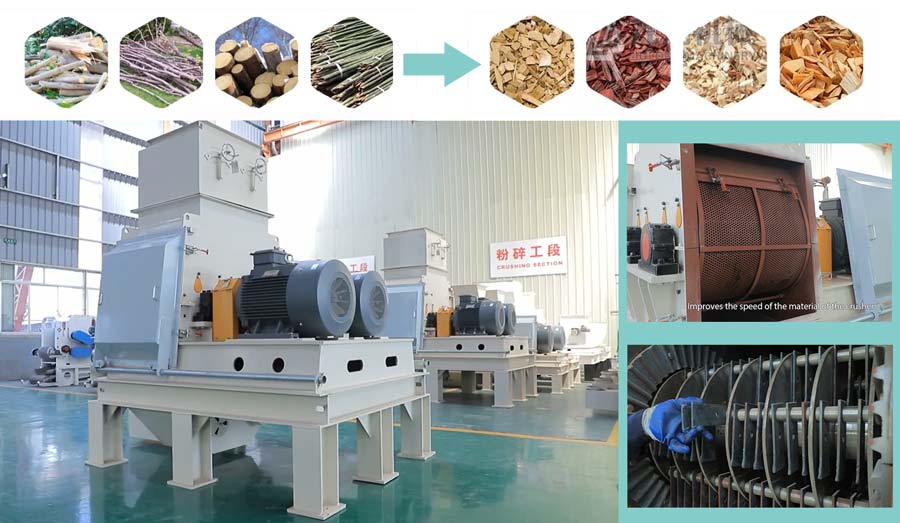

Wood chipper application: logs, branches, veneers, waste veneers, bamboo, cotton stem and other non wood fiber stems. These raw materials can be cut into wood chips of different specifications at one time, these chips can be used as the basic raw material for making particleboard, fiberboard, non wood-based board and pulping and papermaking.

Features Wood chipper

Wood chipper, also known as wood chip machine, is a special equipment for producing high-quality wood chips. It can cut pine, miscellaneous wood, poplar, Chinese fir and other logs and moso bamboo into uniform pieces. It can also slice various materials such as veneer, veneer, bamboo branch, corn stalk, cotton stalk, reed and other non wood fiber poles. Users can adjust the specifications of wood chips within a certain range according to their needs. The product has regular discharging rules and high output. It is an ideal equipment for the material preparation section of industrial production such as paper mill, wood-based panel and medium fiber board and all kinds of wood chip production bases. All models can be customized according to customer needs.

1. This product optimizes the rotor structure and blade material, so that the output is larger and the rotor maintenance is convenient

2. The bearings are optimized in the form of labyrinth, so that dust is not easy to enter. The bearings are equipped with automatic lubrication device, which does not need manual lubricating oil filling.

3. Optimize the electrical system, adopt automatic control and remote control operation, if the upper rotating part of the machine encounters resistance, it will automatically reverse rotation, so as to protect the main motor from high load operation.

4. The frame of the whole machine is made of square tube manganese steel, which is widened and lengthened to ensure the stable operation of the machine.

5. Screen mesh size is customized for different requirements on size of end product.

Features Wood Crusher

Wood crusher, also called root crusher, is a crushing mechanical equipment for all kinds of tree roots, stump, wooden stump and tree bumps. There is a simple and reasonable design of wood chip machine, disk tree stump machine price, easy to operate, compared with similar products is the processing of wood chip products with high capacity, so the choice of disc type wood chip machine is advanced products, but also effective wood chip machine. Disc wood machine can undertake a separate processing, can also cooperate with some transportation equipment or peeling equipment for processing, the machine will log into the feed port, high-speed rotating cutter for cutting material warning, wear-resisting of chrome plated mounted on the cutter blade, disc the stump which machine is good, running a sharp blade will cutting into going to the size of the wood, wood materials are uniform. All models can be customized according to customer needs.

1. This product optimizes the rotor structure and blade material, so that the output is larger and the rotor maintenance is convenient.

2. The bearings are optimized in the form of labyrinth, so that dust is not easy to enter. The bearings are equipped with automatic lubrication device, which does not need manual lubricating oil filling.

3. Optimize the electrical system, adopt automatic control and remote control operation, if the upper rotating part of the machine encounters resistance, it will automatically reverse rotation, so as to protect the main motor from high load operation.

4. The frame of the whole machine is made of square tube manganese steel, which is widened and lengthened to ensure the stable operation of the machine.

Advance of wood crusher:

1. Advanced structure and reliable technology

2. High throughput capacity and high quality chips

3. Low-maintenance and environment-friendly

4. Cost-efficient and space-saving

5. Chipping of all kinds of wood

6. Guaranteed long running time

7. Hydraulic control, simple operation, easy maintenance.

Inquiry Get Price List

Dear, please kindly inform us informations as following:

1. please tell us your expection on production capacity, (kgs/h, or CBM/h).

2. what are the diameter range of your raw materials, (mm)

3. what is your required size of final wood chiper, (length / width / thickness) ? or please tell us your usage of final wood chips, for paper plant, power plant, fuel pellet & briquette making line.

4. whether there are electric power supply in the working area, and the electric power (Voltage, HZ)

5. if your raw material also include branch, board, waste furnature, small wood block, and wood barks, please kindly tell us, we will give you the best suggestion.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 103 countries all over the world, trustable quality & services for lifespan.

Chinese

Chinese

English

English

.png)