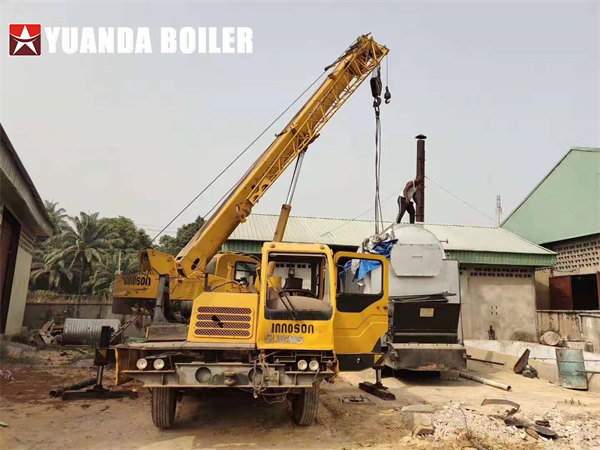

200000Kcal 240KW Diesel Gas Fired Thermal Oil Heater Boiler For Refinery Oil Industry

Small diesel gas fired thermal oil heater boiler, also named thermic fluid heater. 200000kcal thermal capacity 240kw thermal oil boiler for oil mill. Thermal oil heating system, temperature in 250degree.

Thermal Oil Boiler, Thermic Fluid Heater, Hot Oil Heater

Our products are certified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, ensuring high quality and compliance with international standards.

Aavailable fuel: Gas, Diesel, Heavy oil, Coal, Biomass, Electrical

Usage: Heating oil system, For Textile, Food, Chemical, Plastics, Rubber, Paper, Plywood, Building materials, Synthetic fiber, etc.

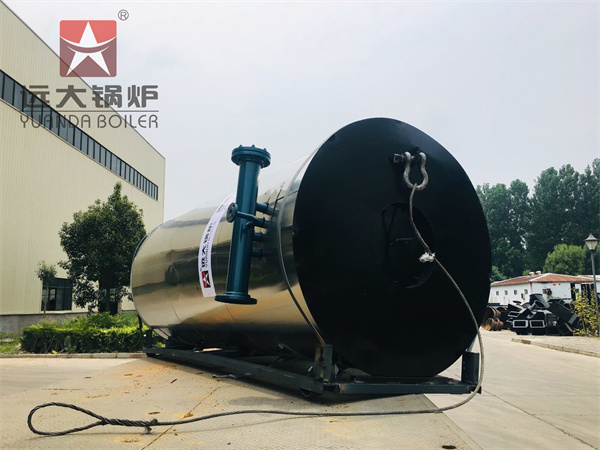

Hot Sell Diesel/Gas Thermal Oil Boiler

YYQW series thermal oil boiler, adopt horizontal chamber combustion three-coil structure, its body is composed of outer oil, middle oil, inner oil and rear oil.