Home » Case » Industrial Gas Fired Boiler 30ton/hr Steam Boiler For Battery Industry

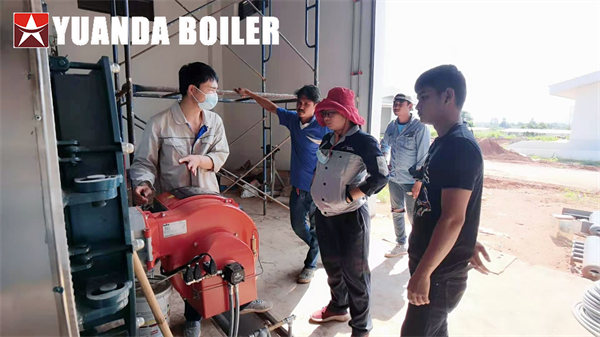

Industrial Gas Fired Boiler 30ton/hr Steam Boiler For Battery Industry

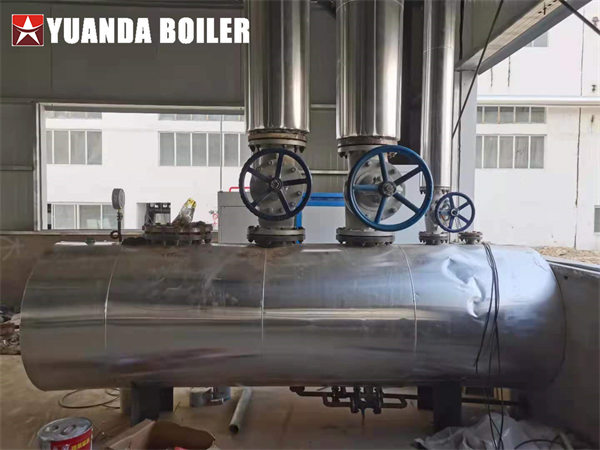

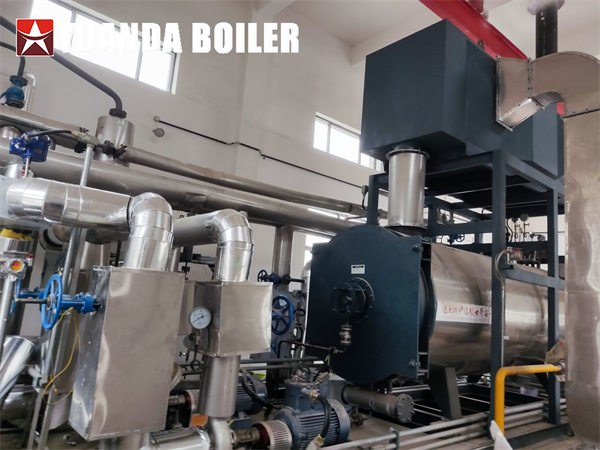

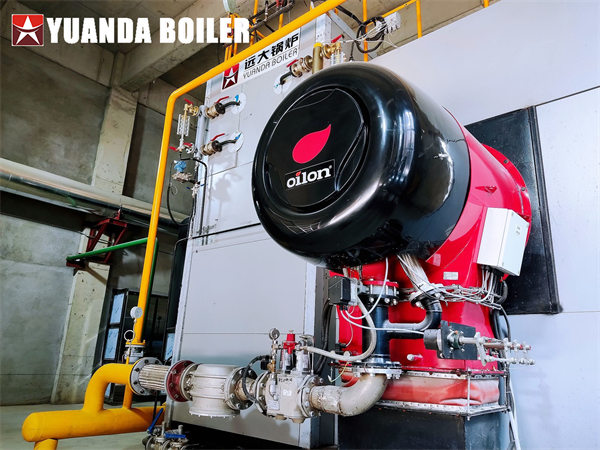

Optimize your steam generation capabilities for the battery industry with the Industrial Gas Fired Boiler. This high-capacity steam boiler is specifically designed to meet the demands of the battery industry, delivering efficient and reliable steam production. With its gas-fired operation, it ensures cost-effectiveness and reduced environmental impact. With a capacity of 30 tons per hour, it meets the requirements of large-scale battery manufacturing operations. Trust the Industrial Gas Fired Boiler to provide consistent and clean steam, enhancing productivity and meeting the stringent quality standards of the battery industry. Experience reliable and high-quality steam for your battery production processes.

Contact US

Get Price

Share:

Content

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible

More Diesel Fuel Oil Gas Boiler