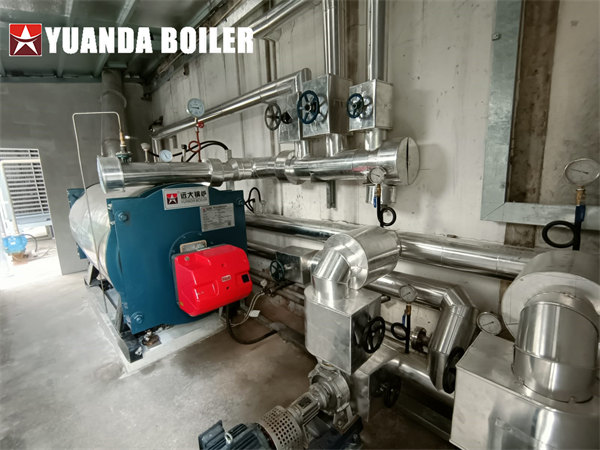

Electric Thermal Oil Heater operates in a closed loop circulation system with minimal pressure. The primary circulating pump provides the flow in the system to take the heat from the electric heater and transfer it to the users. Electric Thermal Oil Heater can reach 350° C, HOS are custom designed for many process applications such as Roller, Presses, Mold, Jacketed Vessel, Exchanger, Mixers, etc. HOS series thermal fluid system is the most compact temperature control system.

The whole system includes an electric heater, centrifugal pump, expansion tank, control center, strainer, stop valves, platinum resistance thermometer sensor, pressure gauge with electric contact, alumina silicate fibre insulation and connecting piping mounted on a welded steel base.