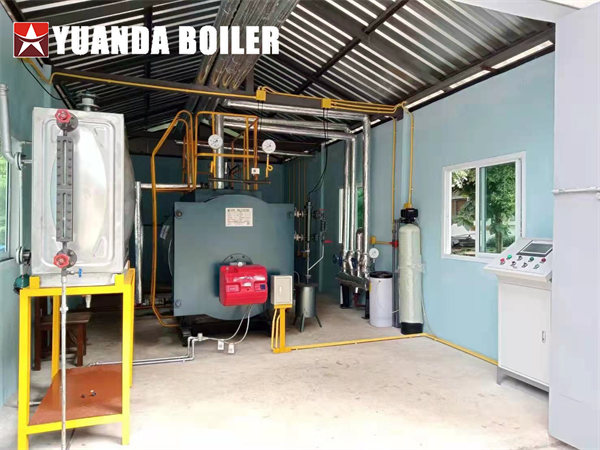

Food Beverage Company Use Coal Steam Boiler 20Ton/Hr

Boiler introduction

1.Boiler model: SZL

2.Boiler capacity: 1-20ton/h

3.Pressure: 1.0Mpa(10bar),1.25Mpa(13bar),1.6Mpa(16bar),2.5Mpa(25bar)

4.Steam temperature: 184 °c,194°c, 204°c,226°c (As long as below 226°c,we can do it)

5.Fuel: wood,rice husk,coconut shell,bagasse,peanut shell,biomass pellet

SZL series water tube boiler is a new design offset hearth (D-type layout), great apply for biomass fuel, environmental protection and energy conservation, and is a key promoted product of national energy-saving projects.

Characteristic

1.A Grade Steam boiler

2.Lower fuel consumption.

3.Lower power consumption.

4.Lower heat losses.

5.Stable operating efficiency of the boiler

6.Boilers are completely trimmed, packaged boilers.No additional fuel train items or electrical wiring is needed.

7.Integrating with explosion gate, digital control system guarantee the boiler is safe.

The furnace type is double-drum,offset furnace, D-type layout, large furnace space, suitable for biomass boiler combustion.Design independent whirlwind burning chamber, with level dust function.Water pipe boiler,large heating area, boost fast.