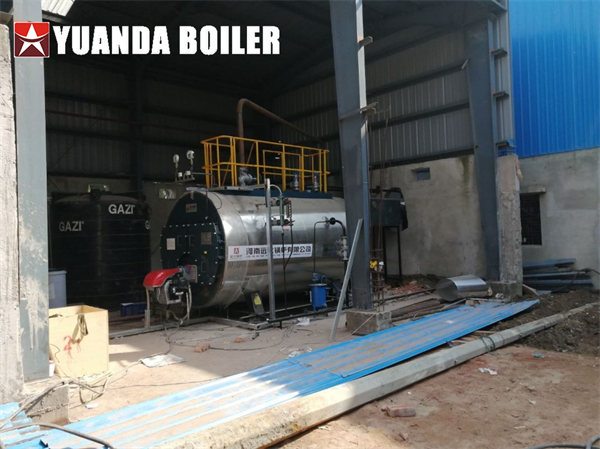

DZL 6Ton Coal Steam Boiler For Rice Parboiling & Drying In Rice Mill Bangladesh

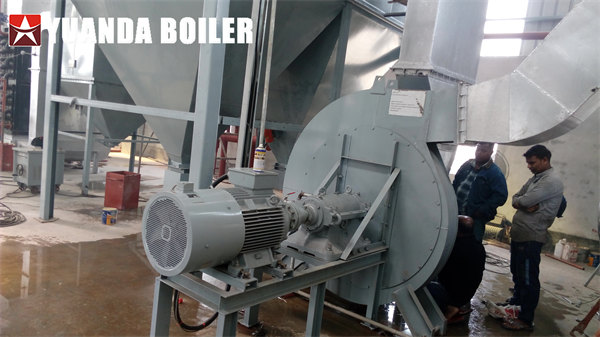

DZL series steam boiler is the kind of automatic, horizontal, three-pass, and fire tube boiler; water wall tubes are arranged along both sides of the inner furnace; it is equipped with high efficiency cyclone, and dust concentration can meet the environmental requirements of second-class area; equipped with Induced Draft Fan and Forced Draft Fan.

Details about the boiler:

1.Fuel:Coal,solid fuel,anthracite,bitumite,lignite

2. DZL Chain grate stoker boiler,automatic burning

3. Single drum,water tube and fire tube boiler

4. Sufficient and Steady Capacity

5. Rapid Warming and High Heat Efficiency

6. Low Original Dust Discharge Concentration, Environmental Protection and Energy Conservation

7. High Steam Quality

8. Strong Water Quality Adaptability

9. Small Overall Dimensions and Low Boiler Room Investment Cost

10. Low Operating Cost, Safety and Reliability

11. Short Installation Time, Low Installation Cost.e combustion efficiency.