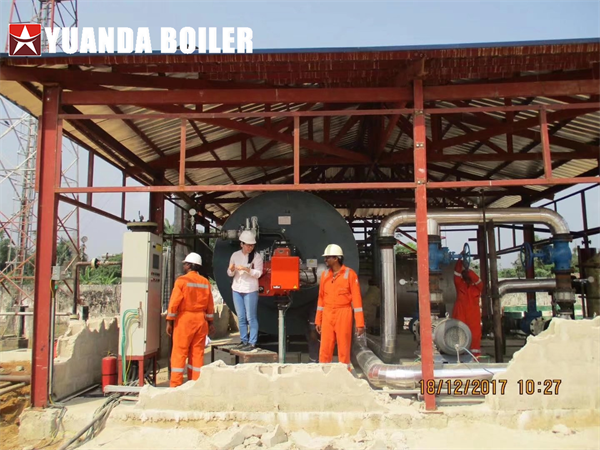

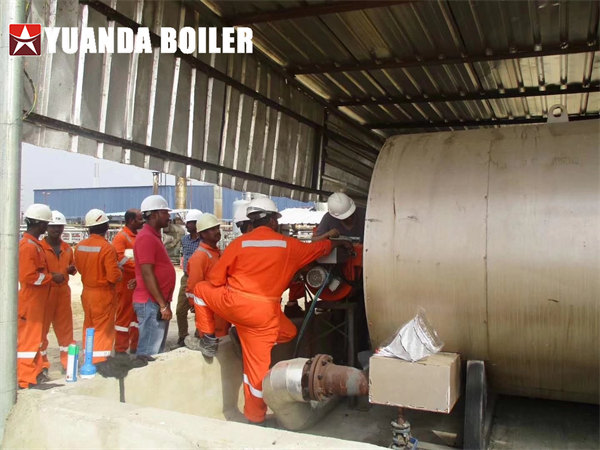

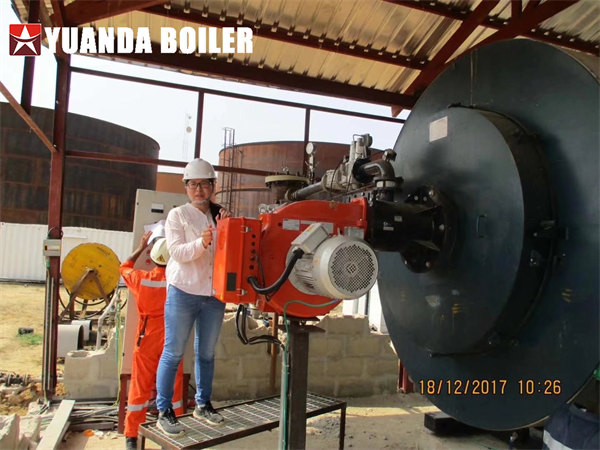

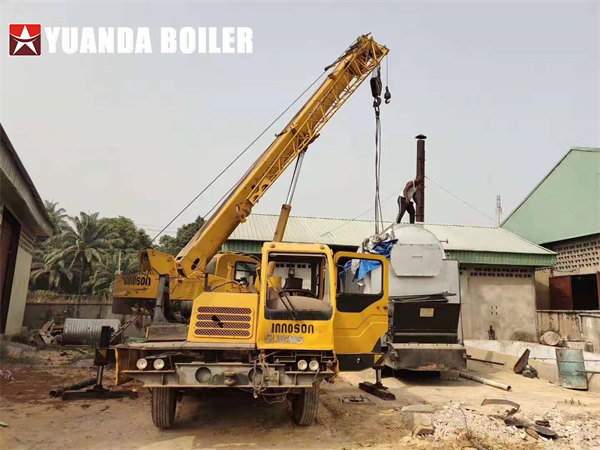

4200kw Gas/Diesel Thermal Oil Heater Boiler Installed in Oilfield Nigeria

YY(Q)W series of organic heat carrier boiler is quick-fitting forced circulation fuel oil(gas)boiler,this series boiler’s is compact structure,the heating area is constituted by closed coil pipes from inside(or internal and external),inside coil pipes are the radition heating surface.Fuel in inside theinner coil pipe form the combustion chamber,the fuel burn inside and release heat and absorb most of the quantity of heat after radiation heating,high temperature flue gas transfer heat through convection heating surface,then go into the air preheater (or waste heat boiler) to heat the required air(or water) ,the low temperature flue gas from boiler discharge directly to the chimney then to the atmosphere.

Thermal oil heater advantages

1.It is easy and convenient to install the boiler,only setting the boiler on the foundation.

2.Heating surface is formed by round coilers, sufficient arrangement, reducing thermal load of tubes surface to ensure safety.

3.Furnace dimensions is matching with the combustion flame,positive pressure combustion,high radiation heat exchange efficiency.

4.Boiler structure is compact,saving the floor area of boiler room.

5.An air pre-heater or heat recovery boiler is placed behind the boiler to improve the thermal efficiency.