Home » Products » Biomass Wood Boiler » Indonesia Palm Oil Mill Service Biomass Palm Fibre Fired Boiler 8ton/hour

Content

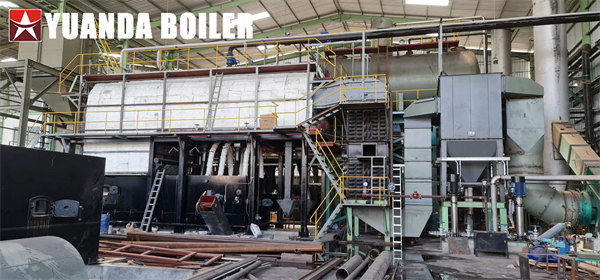

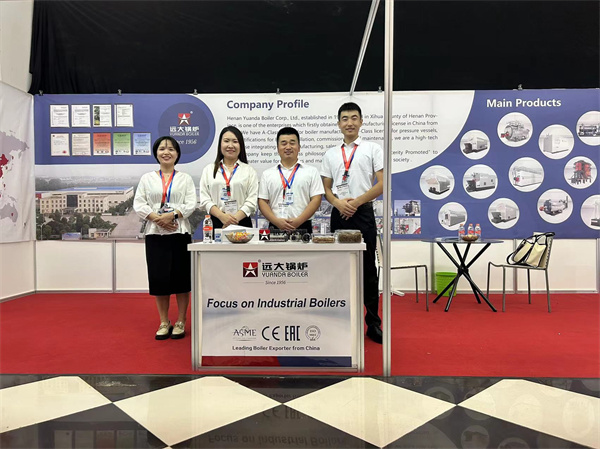

Recently, our senior engineer Mr. Gao and boiler design export Mr. Zhou came to Indonesia customers factory site, working for installation guiding, boiler commissioning, operator training service. Our team collaborated closely with the local engineers to address any unique challenges posed by the site conditions and operational requirements. We are proud to contribute to the growth and sustainability of the palm oil industry, ensuring that operations are not only efficient but also environmentally responsible. Yuanda Boiler Company has sold lots of boilers to Indonesia Companies, professional boiler solution service & high-quality boiler for customers, widely used in Textile, Garments, Plywood Veneer, Food Beverage, Feed Mill, etc.

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible

More Indonesia Projects